Building a $1 Microscope: Foldscope and Beyond Innovations

Written on

Introduction to Affordable Microscopy

The discussion began with a compelling question: What is the most effective microscope you can assemble for under $1 in materials? This inquiry drove inventors Manu Prakash and Jim Cybulski to develop a paper microscope known as the Foldscope. Their aim was to provide an accessible way for individuals to explore their surroundings, whether examining materials found on the ground or in their hands.

Foldscope: Revolutionizing Learning

Every day, I stumble upon fascinating stories in the realms of STEM, STEAM, Education (thanks to the outstanding educators I follow), 3D Printing (also known as Additive Manufacturing), Materials Science, and within maker communities and startups harnessing these innovations. Previously, I primarily shared these insights in more confined settings for various clients, projects, or publications. It often felt as though I wasn't disseminating these valuable discoveries widely enough. With this in mind, I am eager to launch a new publication on Medium, although I have yet to finalize a suitable title that encompasses my diverse research interests.

A few years back, I played a pivotal role in launching and continue to manage a specialized publication called AM News, supported by a National Science Foundation grant project named the Technician Education in Additive Manufacturing & Materials (TEAMM). This initiative focuses on technician education, allowing me to engage in enriching dialogues with professors and industry experts from both two-year and four-year institutions about the latest and most effective educational strategies for a wide range of ages, from high school students to workforce development programs.

As some of my readers are aware, I maintain active collaborations with major companies and brands, particularly in education. I have contributed articles to well-known publications such as the Harvard Business Review, Wall Street Journal, Make magazine, and currently, I write for Forbes in their Innovation and Consumer Tech section.

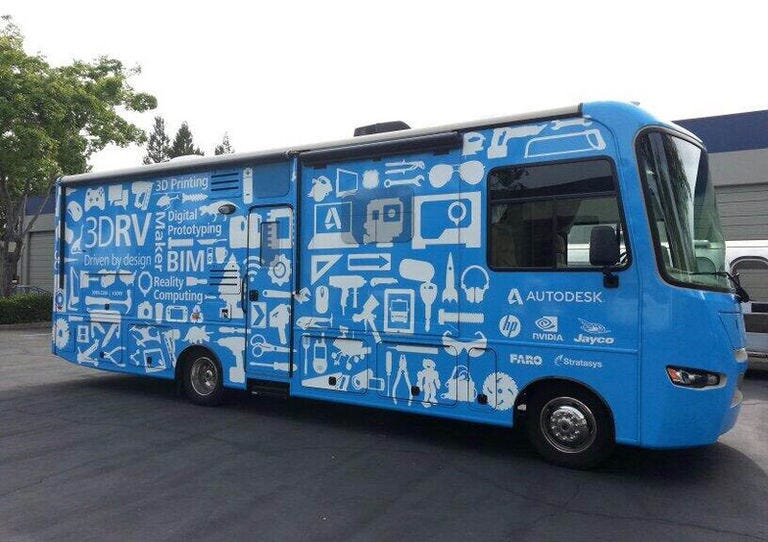

My journey also took me across the United States for nearly a year as part of a national initiative called 3DRV, where I researched and reported on 3D printing and scanning technologies. I am deeply passionate about this field and am committed to preparing our youth for the future workforce. After years of contemplating how to bridge these seemingly disparate areas, I believe I have finally discovered a viable approach.

Moving Forward with Innovation

The solution is simple — just take action, as the famous sneaker brand suggests. I previously doubted my ability to merge these two fields, believing they were too divergent. However, I am ready to move past that limitation. While I am uncertain about how this chapter will unfold, I am eager to progress (and perhaps make some missteps along the way). I invite you to join me on this journey. A newsletter option will be available to share and publish most of my findings, as well as updates here.

Each year, numerous conferences and events vie for our attention. Although I reduced my travel for such events, I plan to reintegrate a few into my schedule. Depending on your interests, you might explore events focusing on Materials Science, STEM Education, or 3D Printing — all of which are relevant to readers here.

On the educational front, TEAMM was part of the annual M-STEM event held last year at the Colorado School of Mines in Golden, Colorado. This event is sponsored by the National Science Foundation as part of an Advanced Technological Education initiative alongside MatEdU, its partner organization at Edmonds Community College.

At the 2019 M-STEM event, two graduate students presented their award-winning project from Tennessee Tech University, where they developed a mobile 3D printer capable of using a variety of materials, from cake frosting to cement. You can view their innovative work in this YouTube video.

Additionally, Somerset Community College is making significant strides in 3D printing by transforming $450 polymer (FFF) machines into metal 3D printers. These examples illustrate just a fraction of the remarkable work being done in this space.

If you haven't explored MatEdU yet, it's a fantastic resource offering teaching materials, including labs, hands-on demonstrations, modules, and papers that can easily be integrated into various courses and industry settings.

Looking ahead, mark your calendars for April 20–23, 2020, for RAPID + TCT, one of the most renowned conferences in the field of Additive Manufacturing, celebrating its 30th anniversary. I will attend this year’s event in Anaheim, California, and will bring back insights on the latest advancements in Medical Additive Manufacturing and emerging startups reshaping the fast-evolving world of 3D printing.

As for those $1 microscopes, by the end of 2019, the Foldscope initiative had distributed a million units, inspiring children and adults alike to develop a passion for learning and curiosity about the world around them, ultimately becoming lifelong citizen scientists. That, to me, is a meaningful way to invest one's time and focus.

May your week be filled with creativity and the joy of making with your own hands, using all the wonderful materials you can find or acquire.

Note: While the Foldscope is constructed from commonly available materials, their deluxe model retails for approximately $30. This pricing likely helps fund other aspects of the initiative. They also offer a classroom kit priced around $20, which translates to just over $1.75 per unit — still an excellent value.